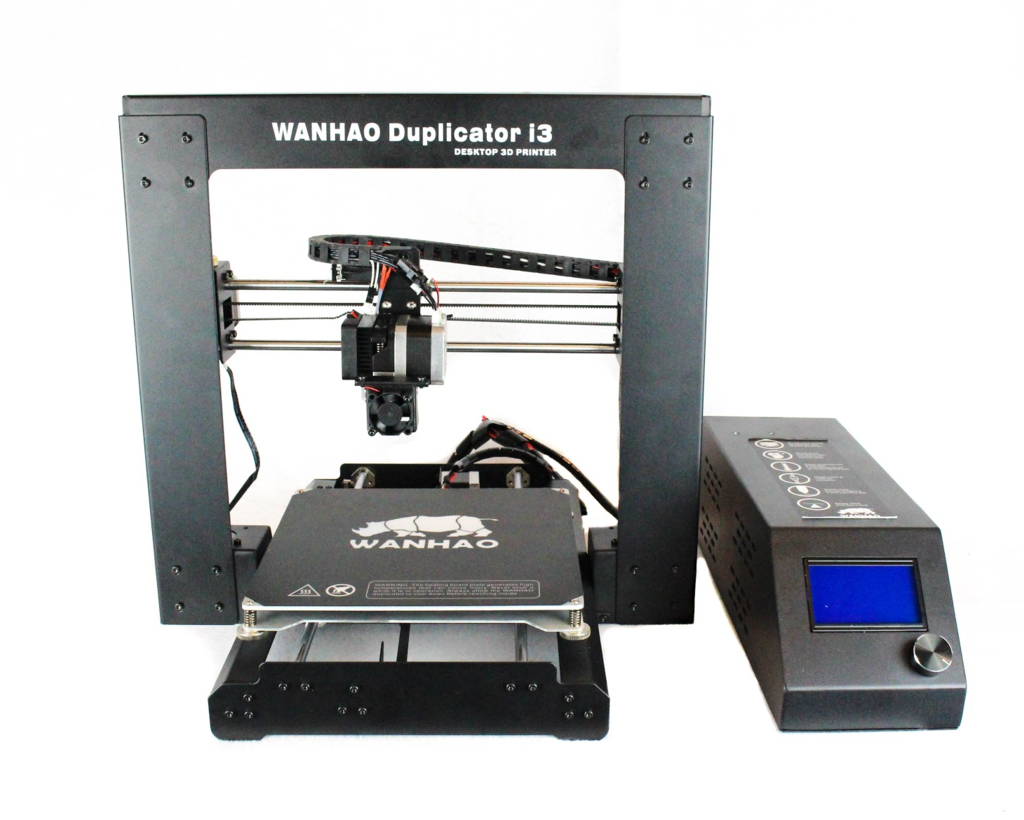

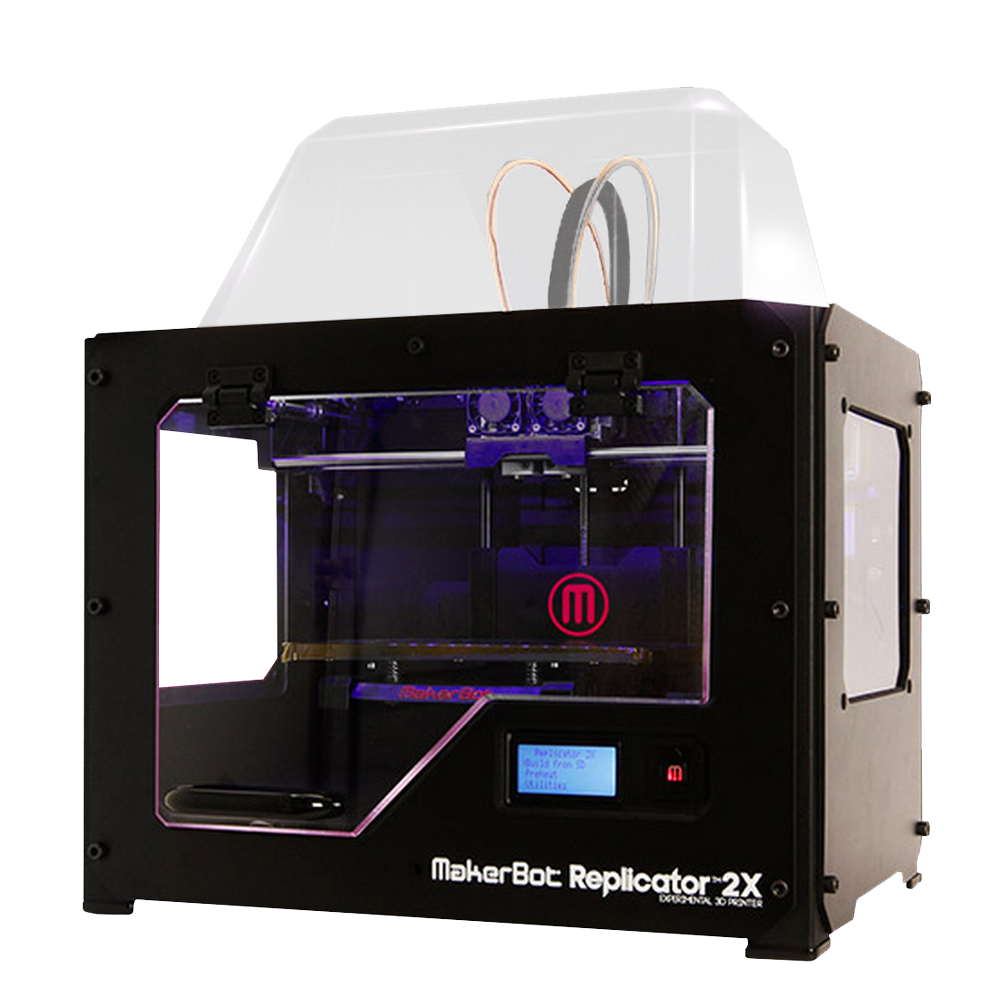

After my returning to my original workplace, I’ve spent several weeks playing around 3D printers, including Wanhao Duplicator i3, Formlab Form1, Makerbot Replicator 2X. Those 3D printers are quite amazing, and it always amuses me how modern mechanical systems work.

I spent several evening during the last several weeks after work disaabmbling and assambling the Makerbot Replicator 2x, and finnaly figured out how it works (I thought Formlabs’ Form 1+ would be as expensive as $5000, so I’m not really comfortable to take it apart. But it actually costs only around $2200). Here is the document on my understanding of 3D printers.

Wanhao Duplicator i3 and Makerbot Replicator 2x are essentially two machines that are quite similar, they are both so called FDM printers, FDM stands for Fused Deposition Modeling. Don’t be scared of the name, it actually quite simple. It follows these steps: First, melt special plastic (PLA or ABS) from room temperature to a quite high temperature (around 190 centidgree for PLA or 220 centidgree for PLA), at this high temperature, these plastic would become very thick liquid (imaging melted icecream), then we force these liquid through a tiny bit hole (0.4mm diameter) in a metal head, and drip them to a plat continuously. The metal head would move both in X and Y axis, leaving a thin trace of liquid plastic. Those liquid plastic would rapidly become solid again exposing to lower temperature. With these solid plastic lines, the metal head draws on a 20cm X 20cm plat line by line and forms a layer. After each layer, there is a motor to lift the metal head up slightly (0.1mm ~ 0.2mm based on settings), and continue to cycle. Layer by layer, the printer is able to construct the 3D printer work slowly but firmly.